Air Heaters

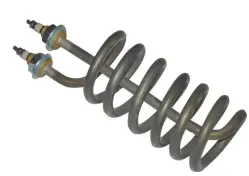

Industrial Air heaters work by radiating heat into the passing air/fluid. Unfiltered air may contain dirt, grease and water which will reduce heater life, especially for open coil air heaters. A time delay relay will keep an air flow over the air heating element for some time even after the heater is turned off. If the temperature sensor is far downstream from the air heating element, place an over-temperature sensor close to the air heater itself. The big advantage of wire wound heating elements made from resistance wire is the low pressure drop across the heating elements compared to tubular heaters.

We recommend the use of a fluid flow switch in the air stream to avoid any overheating of the system in case airflow is restricted (for example due to a dirty air filter, blower failure) and therefor insufficient for the design criteria's the heater was build for. To increase heater life, use a phase-angle fired SCR instead of electro-mechanical relays and SSR's.

Our staff is solving many air heating problems for customers (for example Proheco, Delta-Flo) and resistance wire we can offer a quick turn around for new and repaired wire wound heaters. Wire wound heating (also called coiled wire) elements are also used in small and large heat treat furnaces where they are embedded into ceramic plates or supported by ceramic tubes.

Industrial air heaters are commonly used in:

- high temperature ovens

- convection ovens

- medical packaging industry

- adhesive curing (tri-seals, cartons, etc)

- heat shrinking (bulk packaging, etc.)

- deflashing molded parts

- drying

- staking, forming and bending of plastic