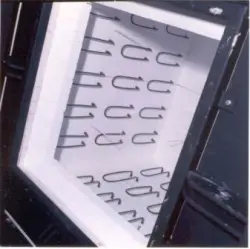

MoSiO2 Elements (MolyD or Molybdenum Disilicide)

Molybdenum disilicide (MoSi2) elements are available in a variety of shapes and sizes and feature the highest operating temperatures and watt loadings of the elements under consideration. (1850C) They also have stable resistance, which allows new and old elements to be connected in series. Fast thermal cycling is possible without element degradation, and the elements are relatively easy to change while the furnace is hot. MoSi2 elements also offer the longest inherent life of all electric heating elements.

Molybdenum disilicide elements are manufactured in several grades of elements, with the primary difference being the MET in a certain atmosphere. The METs in non-air atmospheres and vacuum are significantly higher than those for metallic or SiC elements due to the stability and regeneration characteristics of the protective layer that forms on the surface. If the elements are used at low temperature in air, an oxidation can occur at around 550C that produces a yellowish powder on the element surface. This so-called pest oxidation has no detrimental effect on the performance of the MoSi2 heating element, but is a potential source for product contamination, so operation in this temperature range should be avoided.

In recent years, new MoSi2 elements have been introduced to meet the rapidly evolving needs of furnace temperature cycles and atmospheres (and other requirements, such as cleanliness). These elements feature qualities that are optimized for specific applications such as high temperatures in reactive atmospheres (e.g., nitrogen), extreme temperatures with changing atmospheres, high temperatures and rapid cycling in laboratory and high-temperature sintering furnaces and contamination- sensitive high temperature processes. This represents a significant advancement in MoSi2 element technology.

Advantages:

- Available in a variety of shapes and sizes

- Highest operating temperatures and watt loadings of the elements under consideration

- Stable resistance; new and old elements can be connected in series

- Fast, thermal cycling possible without element degradation

- Relatively easy to change while the furnace is hot

- Longest inherent life of all electric heating elements

Disadvantages:

- More costly power control equipment than for metallic elements (low voltage/high startup current, transformer required)

- Most expensive of the elements under consideration

- Ceramic material risk of fracture

The trade names Kanthal Super and Moly-D® are the property of Kanthal Corporation and I Squared R respectively.