Furnace Retorts and Muffles

Muffles and retorts are used to protect goods from the atmosphere during thermal processing. Retorts are used for batch furnaces, while muffles are used in continuous furnaces or kilns.

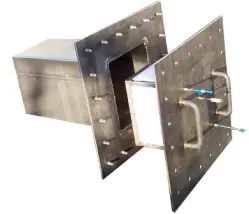

A retort is an airtight vessel. The goods are placed inside the retort (vessel) before exposing it to the process heat. Retorts are commonly connected to gases generating an oxidizing, reducing or inert atmosphere in the retort.

Muffles are used as an inner chamber on pusher kilns and belt furnaces, where the goods are placed into a boat or on a belt and then transported through the furnace in a defined atmosphere. Muffles need very elaborate air seals on the entry and exit to avoid any contamination with air. An oxygen leak in a Hydrogen furnace or kiln can damage the goods and equipment.

We do also build furnaces and kilns where the protective gases are diffused through the furnace lining, thus potentially eliminating the need for a high dollar retort.